What is Polylactic Acid (PLA) Fiber?

Polylactic Acid fiber is really a biopolymer-based synthetic fiber made out of lactic acid, that is fermented from renewable plant-based starches. Unlike petroleum-derived synthetic fibers such as polyester or nylon, PLA is compostable and biodegradable, so that it is a more sustainable choice.

Key characteristics of PLA fiber include:

Biodegradability – It decomposes under industrial composting conditions, leaving minimal environmental impact.

Renewable sourcing – Made from agricultural crops as opposed to fossil fuels.

Comfort and gratifaction – Soft texture, lightweight, and good moisture-wicking properties.

Thermal properties – Low melting point, making it suitable for bonding processes in non-wovens.

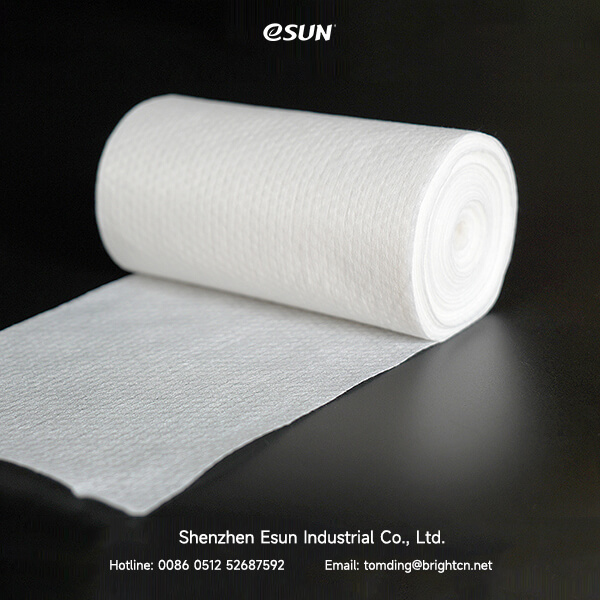

PLA in Non-Woven Fabrics

Non-woven fabrics are engineered materials manufactured by bonding or entangling fibers through mechanical, thermal, or chemical methods, without traditional weaving or knitting. PLA is a wonderful raw material for non-wovens due to its bonding characteristics, biodegradability, and versatility.

Advantages of PLA Non-Woven Fabrics

Eco-Friendly – Fully compostable and reduces plastic waste.

Skin-Friendly – Hypoallergenic, breathable, and well suited for medical and hygiene applications.

Energy Efficient – Lower processing temperatures in comparison to petroleum-based fibers reduce energy consumption.

Versatile Applications – Can be engineered for strength, softness, or absorbency.

Applications of PLA Non-Wovens

Medical and Healthcare – Surgical masks, gowns, drapes, wound dressings, and disposable hygiene products.

Agriculture – Biodegradable crop covers, seedling mats, and mulch films.

Packaging – Eco-friendly bags, shopping totes, and protective wraps.

Home and Personal Care – Wet wipes, diapers, sanitary products, and cleaning cloths.

Challenges and Future Outlook

While PLA fiber and non-woven fabrics are promising, some challenges remain. The cost of PLA production is higher in comparison to conventional plastics, and its particular mechanical strength and thermal resistance might be lower. However, with advances in polymer science, blending technologies, and large-scale production, prices are decreasing, and gratification is improving.

Looking forward, the interest in sustainable textiles and packaging is anticipated to accelerate the adoption of PLA non-wovens. Governments and industries are increasingly supporting biodegradable materials as part of their environmental policies, making PLA an important player later on of green materials.

Polylactic Acid fibers and non-woven fabrics represent a sustainable option to petroleum-based textiles. Combining biodegradability, comfort, and versatility, they're finding applications across healthcare, packaging, agriculture, and private care. As technology evolves, PLA non-wovens are poised to learn a central role in reducing plastic waste and promoting a greener, circular economy.